Products

Welding Consumable Plant

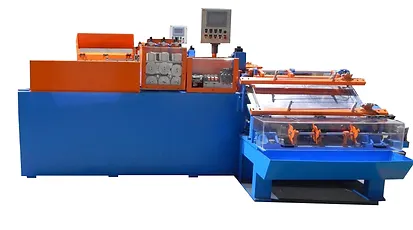

FCW Line

We have adequate experience to design & manufacture Flux cored wire manufacturing Line. The production of Flux Cored Wire begins by joining / butt welding many Pan Cakes of strips to form a single long strip wound on a bobbin, for continuous feeding to get maximum productivity.

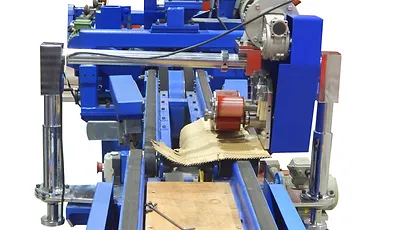

Tig wire cutting machine

These machines are specifically designed for wire straightening and cutting in welding electrode production, are engineered with precision to meet industry standards. The robust construction ensures longevity and reliability, making them cost-effective for manufacturers.

Rotating Die holder

Rotating die holders are indispensable for high-speed wire drawing machines, optimizing performance and longevity. These holders effectively mitigate die wear by facilitating even distribution of stress across the die surface. This uniform wear pattern prevents ovality and ensures prolonged die lifespan.

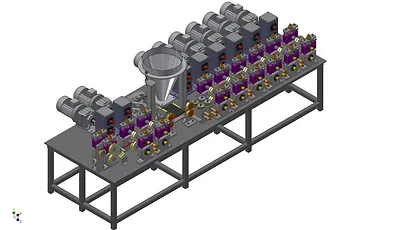

Killing Roller Assembly or Wire Straightener

Mahani Engineers make Killing Rollers Assembly for removing the Cast & Helix from the MIG wires & SAW wires before they are wound on a bobbin/plastic spool.This is achieved by 2 sets of grooved rollers arranged in both the horizontal and vertical planes.

Welding Electrode Line

Our Extrusion Plant and Conveyor systems are tailored specifically for the efficient production of Stick Welding Electrodes, offering a range of capacities and technical specifications to meet diverse manufacturing needs. These robust plants are engineered to ensure seamless transportation and installation at any site.

Printing Unit

Our Electrode printer is a specialized solution meticulously engineered for printing directly onto wet electrodes immediately after they exit the Extruder, prior to baking. This innovative system features precision-ground inking rollers and transfer rollers.

Contact Us

- info@mahaniengineers.com

- +91 9762201376

- +91 9922535540

Contact Us

- info@mahaniengineers.com

- +91 9762201376

- +91 9922535540